APC

78 products

Showing 1 - 48 of 78 products

Showing 1 - 48 of 78 products

Display

View

Clearance!Save 25%

Sale price$ 3.35

Regular price$ 4.49

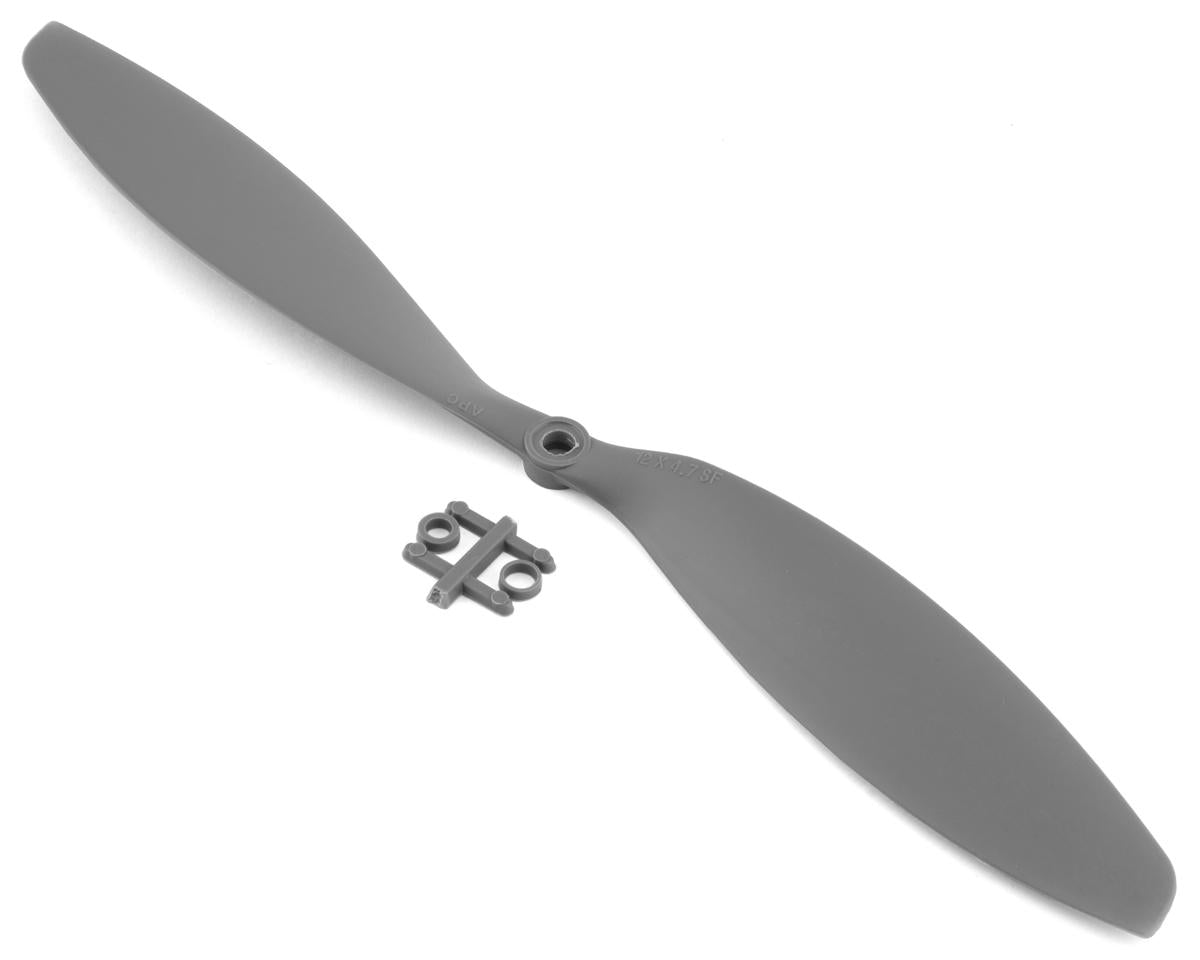

APC 12x4.7 Slow Flyer Propeller *ClearanceAPC

In stock, 7 unitsClearance!Save 25%

Sale price$ 4.10

Regular price$ 5.49

APC 13x6.5 Thin Electric Pusher Propeller *ClearanceAPC

In stock, 3 unitsClearance!Save 28%

Sale price$ 5.75

Regular price$ 7.99

APC 15x4EP Thin Electric Pusher Propeller *ClearanceAPC

Only 1 unit left

Filters (0)